While China is a popular choice for sourcing retail and ecommerce goods, it can also be a great strategy for finding cost-effective machinery.

However, the process is more complex than sourcing other products. This guide will outline the steps involved and explain why using a sourcing specialist is crucial.

Benefits of Sourcing Machinery from China:

· China’s comparatively low labor costs often result in lower machinery prices.

· While product quality can vary among suppliers, it’s often high due to China’s skilled workforce and advanced manufacturing facilities.

· China hosts well-established machinery industrial clusters, particularly in regions like Shanghai, Jiangsu, Guangdong, and Shandong provinces, where suppliers specialize in various machinery fields.

Challenges and Why a China Machines Sourcing Specialist is Essential:

· Finding Reliable Suppliers: Verifying capabilities and qualifications is critical to avoid defective machinery.

· Quality Control: Unlike retail products, defective machinery can cause significant problems.

· Communication and Regulations: Language barriers and export regulations require expertise.

How to Buy Machines from China?

1. Find the Right Supplier

Don’t rely solely on online directories. A sourcing specialist can help you identify reputable suppliers with the necessary experience and capabilities for your specific needs.

The majority of machinery manufacturers are concentrated in and around Shanghai, with additional presence in Guangdong, Jiangsu, Zhejiang, and Shandong provinces. To ensure product quality, engaging a third-party organization to conduct on-site supplier or factory audits on your behalf can be beneficial.

Numerous online resources offer directories of companies specializing in specific heavy machinery that match your requirements. Establishing communication in China allows for building relationships and outlining your organization’s needs effectively.

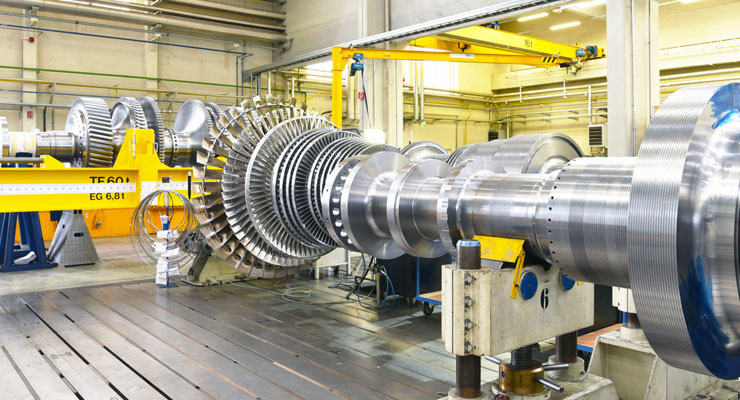

Types of Common Machinery Manufactured in China

·Wheel Loaders

·CNC Machines

·Laser Cutting Machines

·Agriculture / Food Production Machines

·Roll Forming Machines

·Welding Machines

·Packaging & Printing Machinery

2. Production with a Chinese Supplier

Actively monitor quality control. Ideally, be present at the factory or have inspections conducted. Ensure machinery meets safety standards for your destination country.

Arrange for necessary testing to verify functionality and compliance with regulations.

Oversee test runs to ensure the machinery works as specified.

3. Importing Machinery from China

·Sea Freight: Book a container well in advance and choose the right size. Expect additional costs for secure packing.Winsail logisitics team will help you to handle your shipment professional.

·Port Congestion: Schedule shipments outside peak periods and consider FCL (full container load) if feasible.

·Customs Clearance: Prepare all required paperwork beforehand, including certifications relevant to your machinery.

4. Final Shipping and Domestic Considerations

Schedule domestic freight transport (truck or rail) and arrange for unloading equipment if necessary.

Be prepared for potential chassis shortages and road weight limits, which might require alternative routes.

Machinery will likely require recalibration after shipping, which can take a week to a month.

-

A Comprehensive Guide to Refrigerated ContainersJun 17,2025

A Comprehensive Guide to Refrigerated ContainersJun 17,2025 -

Guide to 20ft & 40ft Shipping Container Dimensions for Global LogisticsJun 17,2025

Guide to 20ft & 40ft Shipping Container Dimensions for Global LogisticsJun 17,2025 -

How to track shipments sent from ChinaMay 13,2025

How to track shipments sent from ChinaMay 13,2025 -

Guide to Importing and Shipping Cars from China to UAEMay 13,2025

Guide to Importing and Shipping Cars from China to UAEMay 13,2025 -

Guide to Importing and Shipping Camping Gear from ChinaMay 07,2025

Guide to Importing and Shipping Camping Gear from ChinaMay 07,2025 -

Shipping from China to YemenMay 06,2025

Shipping from China to YemenMay 06,2025