At Winsail , we recognise that handling special cargo is different from traditional container shipping.

With more than 40 years of experience in transporting oversized and heavy shipments and an unparalleled global network, we have the capacity to deliver your special cargo to any part of the world. Our international team of special cargo experts have an in-depth knowledge and understanding of the challenges involved, and are there to help throughout the entire process.

Experience the ease and convenience of dealing with a one-stop shop

Spend your time and efforts on your business and not on coordinating with multiple qualified sub-tier vendors and suppliers to accomplish your project cargo goals.

We ship all types of special cargo

Oversized and overweight cargo is characterised by exceeding the proportions and capabilities of a single standard container. Whether you are shipping a 350-ton tugboat, a 46-metre crane arm or a 17-metre propeller, we have the expertise and equipment available to deliver.

We provide tailored and efficient solutions for shipping your In Gauge, Out of Gauge and Break Bulk cargo.

In Gauge cargo

The dimensions of the cargo are smaller than or equal to those of the flat rack or open top container (i.e. it requires special equipment but does not displace additional slots on the vessel).

Examples of In Gauge shipments: machinery or large trees that can be lowered into an open top container.

If you are shipping In Gauge cargo, you can book your shipment in just a few minutes on Maersk.com.

Out of Gauge cargo

The dimensions of the cargo exceed the flat rack or open top container by length, width or height, but can still be unitised in containers.

Examples of Out of Gauge shipments: propellers, flanges or trucks.

Break Bulk cargo

Vastly exceeds the size and/or weight of a standard container and is therefore handled as non-unitised cargo and normally placed on a bed of flat racks with a large number of lashing points.

Examples of common Break Bulk shipments: yachts, masts, industrial machines or train carriages.

Understanding Out of Gauge Cargo

Out of Gauge (OOG) Cargo requires special and delicate handing. In order to handle your OOG cargo safely, it is essential to give a full and accurate declaration of your cargo. It is crucial to not only declare the dimensions and particulars of your cargo accurately, but also to ensure that it is packed correctly to avoid delays and additional costs.

Important points to consider when placing OOG booking

1.Define if cargo is IG or OOG: If cargo dimensions exceed dimensions mentioned in the table above, it must be declared as Out of Gauge cargo.

2.End wall position: Can be either up or down and must be declared accordingly.

3.Weight: Correct gross weight of the cargo must be provided.

4.Lashing equipment protrusions: Lashing equipment protruding outside the container should be taken into consideration when declaring dimensions.

5.Cargo shifting: Changes to dimension due to poor lashing during transit. Your goods need to be secured correctly, considering vessel movements during ocean transport.

6.Extra materials: Crates, lashing materials and dunnage used while lashing the container can change the total cargo dimensions.

Importance of the OOG declaration process

The objective of out of gauge declarations is, first and foremost, to ensure the safety of the crew handling the cargo. It is also practised to minimise operational challenges due to dimension mismatches, which can result in delays.

Let’s take a closer look:

Safety first

Knowing the actual dimensions of your cargo and checking to see if it’s lashed correctly can prevent accidents from occurring.

Any terminal can refuse to load cargo as a safety precaution if the cargo dimensions do not match the declaration.

Operational efficiency

Dimension discrepancies during gate-in or transit result in operational challenges with terminals in terms of capability and restriction. This might lead to disruption in cargo planning and even cargo shut-out.

The space allocation for cargo is planned in slots with the received dimensions. If the dimensions change, these might trigger the slots to change.

-

How to Import Goods from China to Ethiopia?Oct 21,2024

How to Import Goods from China to Ethiopia?Oct 21,2024 -

How to Import from China to EcuadorOct 18,2024

How to Import from China to EcuadorOct 18,2024 -

HongKong PortOct 17,2024

HongKong PortOct 17,2024 -

A guide to importing and transporting playground equipment from ChinaOct 16,2024

A guide to importing and transporting playground equipment from ChinaOct 16,2024 -

Shipping from China to GuineaOct 15,2024

Shipping from China to GuineaOct 15,2024 -

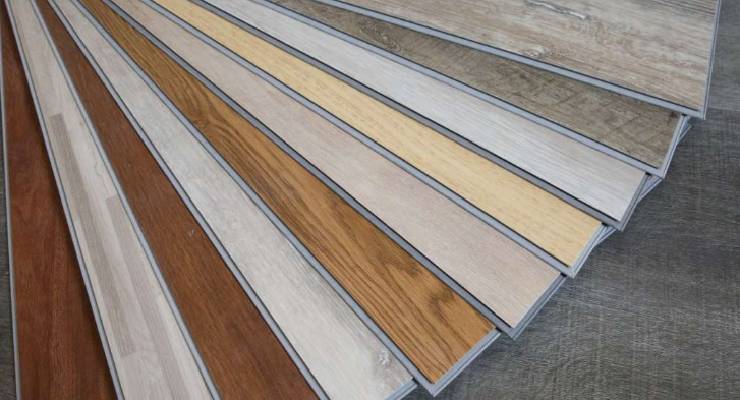

Guide to Importing and Shipping PVC Flooring from ChinaOct 11,2024

Guide to Importing and Shipping PVC Flooring from ChinaOct 11,2024