Logistics Overview of Solar Panels

Shipping solar panels from China involves a combination of fragile handling requirements, high cargo value, and large shipment volumes, making logistics performance a critical success factor. Solar panels are highly sensitive to vibration, compression, moisture, and improper stacking, which means even minor handling errors during loading, transshipment, or inland delivery can result in concealed damage.

From a logistics perspective, solar panel shipments often move in full-container or project-based batches, where container utilization, load distribution, and route stability directly impact cargo safety and cost control. Customs compliance also plays a key role, as misclassification or incomplete documentation may trigger inspections, delays, or unexpected duties in certain destination markets.

Because of these factors, shipping solar panels requires professional freight forwarding coordination, combining proper packaging, optimized transport modes, risk management, and end-to-end visibility from origin to final delivery.

Logistics Characteristics of Solar Panel Cargo

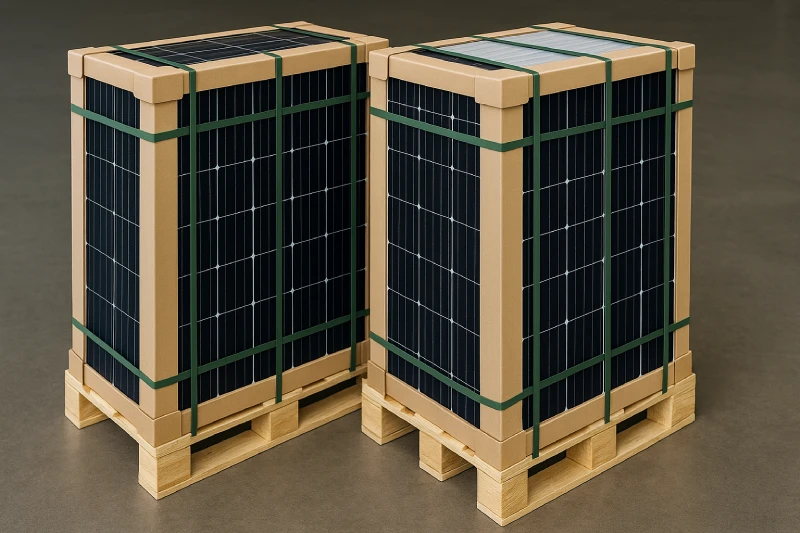

From a logistics standpoint, solar panels are classified as fragile, bulky, and high-value cargo, with strict tolerance limits for handling and transportation conditions. Although individual panels are relatively lightweight, they are typically shipped in large-format cartons or palletized units, resulting in significant volume and space-planning requirements.

The primary logistics challenge lies in the panels’ vulnerability to micro-cracks caused by vibration, uneven pressure, or improper stacking. These damages are often not visible at delivery but can affect performance after installation, increasing claim and dispute risks. In addition, solar panel shipments are frequently consolidated into project-based or multi-container movements, requiring precise coordination of loading sequences, container balance, and delivery schedules.

Because of these characteristics, solar panels demand controlled handling procedures, stable routing, and detailed pre-shipment planning, particularly when shipped via ocean freight or through transshipment hubs.

Shipping Methods for Solar Panels

The selection of shipping methods for solar panels depends largely on shipment volume, delivery urgency, and risk tolerance. For most commercial and utility-scale shipments, Full Container Load (FCL) is the preferred option, as it minimizes cargo handling, reduces exposure to vibration, and allows for controlled loading and internal bracing.

Less than Container Load (LCL) may be used for smaller shipments, but it carries higher risk due to multiple loading and unloading points, increased stacking pressure, and limited control over container conditions. As a result, LCL shipments require enhanced packaging and careful consolidation planning.

Air freight is typically reserved for urgent replacements, sample panels, or high-value shipments with strict delivery deadlines, given its higher cost and size limitations. In certain cases involving oversized frames or non-standard packaging, special equipment or customized container solutions may be required to ensure transport stability.

Transit Time Considerations for Solar Panel Shipments

Transit time for solar panel shipments from China varies based on transport mode, destination region, and routing structure. Ocean freight, commonly used for bulk and project shipments, typically involves longer transit cycles and is more susceptible to port congestion, schedule changes, and transshipment delays. Stable direct routes are often preferred to reduce handling frequency and transit uncertainty.

Air freight offers significantly shorter transit times but is constrained by cargo dimensions, weight limits, and space availability, making it suitable mainly for urgent or time-sensitive deliveries. Beyond the main transport leg, total transit time is also influenced by customs clearance efficiency, inland transportation capacity, and destination warehouse readiness, particularly for fragile cargo requiring specialized unloading.

Effective transit time planning therefore requires buffer allowances, route evaluation, and coordination across multiple logistics stages to avoid project disruptions.

Shipping Cost Factors for Solar Panels

Shipping costs for solar panels are driven by a combination of volume utilization, handling complexity, and risk management requirements. Due to their bulky packaging and limited stackability, container space efficiency plays a major role in overall cost control, particularly for full-container shipments.

Additional cost factors include specialized packaging materials, internal bracing, and moisture protection needed to mitigate damage during long-distance transport. Insurance premiums are also typically higher, reflecting the cargo’s high value and susceptibility to concealed damage. At destination, ports may apply extra handling or storage charges for fragile or oversized cargo, especially if inspections or re-handling are required.

Seasonal demand for renewable energy equipment can further affect freight rates and space availability. As a result, accurate pre-shipment planning and cost breakdown analysis are essential to avoid unexpected logistics expenses.

Packaging & Handling Requirements for Solar Panels

Proper packaging and handling are critical to minimizing damage risks when shipping solar panels from China. Panels are highly sensitive to edge impact, surface pressure, vibration, and moisture, requiring packaging solutions that protect both structural integrity and surface condition throughout the transport process.

Solar panels are typically packed in reinforced cartons or custom pallets, often in a vertical orientation to reduce compression stress. Edge protectors, shock-absorbing materials, and internal separators are commonly used to prevent movement and contact between units. For ocean shipments, moisture barriers, desiccants, and anti-condensation measures are essential to protect against humidity during long transit periods.

Handling procedures must strictly control stacking height, forklift entry points, and lifting angles to avoid micro-cracks or frame deformation. Clear handling instructions such as Fragile, Do Not Stack, and Keep Upright should be visible on all sides. Consistent packaging standards and supervised loading significantly reduce loss and claim risks.

HS Codes & Customs Notes for Solar Panels

Accurate HS code classification is a critical factor in the customs clearance of solar panel shipments from China. Incorrect or inconsistent classification may result in customs inspections, documentation requests, clearance delays, or unexpected duty assessments, particularly in markets with enhanced scrutiny on renewable energy equipment.

Solar panels may be subject to additional regulatory reviews, depending on destination country policies, trade measures, or safeguard controls. Customs authorities often require detailed commercial invoices, precise product descriptions, and complete packing lists that clearly reflect shipment configuration and quantity.

For project or multi-container shipments, consistency across all documentation is essential to avoid partial holds or release discrepancies. Pre-clearance review and alignment with local customs requirements help reduce clearance risk, prevent storage charges at port, and maintain predictable delivery timelines.

Route & Port Recommendations for Solar Panel Shipments

Route and port selection play an important role in reducing handling risks when shipping solar panels from China. Because solar panels are highly sensitive to vibration and re-handling, routes with fewer transshipment points are generally preferred to maintain cargo stability throughout the journey.

Ports with experience handling fragile or project-based cargo are better equipped to manage careful loading, storage, and discharge procedures. Avoiding congested hubs or ports with frequent container restacking can significantly lower the risk of damage and delay. Direct sailings, where available, help minimize exposure to unnecessary movement and schedule uncertainty.

At destination, port infrastructure and inland connectivity should also be evaluated, particularly for large-volume or multi-container shipments requiring coordinated delivery to project sites or warehouses.

Loading Methods & Container Optimization for Solar Panels

Proper loading methods and container optimization are essential to protect solar panels during transit. Depending on shipment size and packaging format, panels may be floor-loaded or palletized, with each method requiring precise planning to control movement and pressure distribution.

When floor-loading, panels must be arranged to maintain even weight distribution across the container floor, with anti-slip materials placed underneath to prevent shifting. For palletized loads, securing systems such as strapping, blocking, and bracing are used to stabilize units and maintain vertical alignment. Empty spaces within the container should be filled or restrained to avoid internal movement during ocean or inland transport.

Before sealing the container, visual inspections and photo documentation are recommended to verify proper loading and securing. Well-planned container utilization not only reduces damage risk but also improves space efficiency and cost control.

Risk Control & Cargo Insurance for Solar Panels

Solar panel shipments are exposed to multiple logistics risks, including vibration damage, moisture exposure, improper handling, and concealed loss. Because many defects are not immediately visible upon delivery, disputes often arise after installation or testing, making risk control a critical logistics consideration.

Comprehensive cargo insurance is strongly recommended, particularly for high-value or project-based shipments. All-risk coverage helps protect against unforeseen transport incidents, while clear documentation supports efficient claims handling if issues occur. Risk mitigation also begins before shipment, through verified packaging standards, controlled loading procedures, and route stability assessment.

Maintaining detailed records, including packing photos and condition reports, further strengthens loss prevention and accountability throughout the transport chain.

Country-Specific Shipping Notes for Solar Panels

Shipping solar panels from China requires consideration of regional logistics conditions and regulatory environments. In the Middle East, high ambient temperatures and extended port storage periods increase the need for heat-resistant packaging and moisture control. Inland transportation planning is also critical due to long-haul deliveries to project sites.

For European destinations, customs procedures often involve stricter documentation reviews and compliance checks, which can impact clearance timelines if paperwork is incomplete or inconsistent. In the United States, solar panel shipments may face enhanced inspection or trade-related controls, making accurate classification and pre-clearance preparation essential.

In parts of Africa and emerging markets, port handling capability and inland infrastructure vary significantly, requiring careful coordination to ensure safe discharge and final delivery without excessive re-handling.

Tips to Reduce Damage, Delays & Extra Costs

To reduce logistics risks when shipping solar panels from China, careful planning should begin well before cargo pickup. Whenever possible, full-container shipments are preferred over consolidation, as they provide greater control over loading conditions and reduce handling frequency. Early booking helps secure stable schedules and avoids peak-season space constraints commonly associated with renewable energy projects.

Packaging standards should be aligned with the chosen transport method and route, with particular attention to vibration protection and moisture prevention. Verifying destination warehouse capabilities in advance—such as unloading equipment and storage conditions—can prevent last-minute delays or handling damage. Close coordination between shipper, forwarder, and consignee ensures smoother transitions across each stage of the supply chain.

How Winsail Logistics Supports Solar Panel Shipments

Winsail Logistics provides end-to-end freight forwarding solutions tailored to the specific logistics challenges of solar panel shipments from China. Our approach begins with shipment assessment and transport planning, ensuring that packaging, loading methods, and transport modes align with cargo sensitivity and project timelines.

We coordinate container space optimization, route selection, and handling procedures to minimize re-handling and reduce exposure to damage risks. For project or multi-container shipments, Winsail manages scheduling, documentation consistency, and destination coordination to support smooth delivery. Our team also assists with customs preparation, cargo insurance arrangements, and pre-shipment inspections, helping clients maintain predictable transit outcomes.

By maintaining close communication across all logistics stages, Winsail helps ensure that solar panel shipments move safely, compliantly, and efficiently from origin to final delivery.

FAQ

Is LCL shipping safe for solar panels?

LCL can be used for smaller shipments, but it involves more handling points and higher stacking risk. Enhanced packaging and careful consolidation planning are required.

Are solar panels considered dangerous goods?

Standard solar panels are generally not classified as dangerous goods, but accurate declaration is still required to avoid compliance issues.

How can damage risks be reduced during ocean transport?

Using FCL shipments, reinforced packaging, proper container bracing, and stable direct routes significantly reduces damage exposure.

What documents are required for customs clearance?

Commercial invoice, packing list, and accurate HS code classification are essential. Additional documents may be required depending on destination regulations.

Is cargo insurance necessary for solar panel shipments?

Cargo insurance is strongly recommended due to the high value and potential for concealed damage during transit.